Every Thing You Need To Know About Mesh Fabric

Mesh is an open-hole fabric built by knitting or weaving yarns into a regular grid, most often in polyester, nylon, cotton or stretch blends. I cover the main mesh types, trace its path from old net and lace ideas to modern sports and technical textiles, and explain how mills form holes through knit or weave settings.

I show how women’s garments use mesh for panels, sleeves, linings and support layers, then list key properties, uses and where production happens. I weigh pros and cons, compare mesh with net and with sheer fabrics so the “holes vs thin cloth” difference stays clear, then close with care rules that stop snags, stretching and heat damage.

What Is Mesh Fabric?

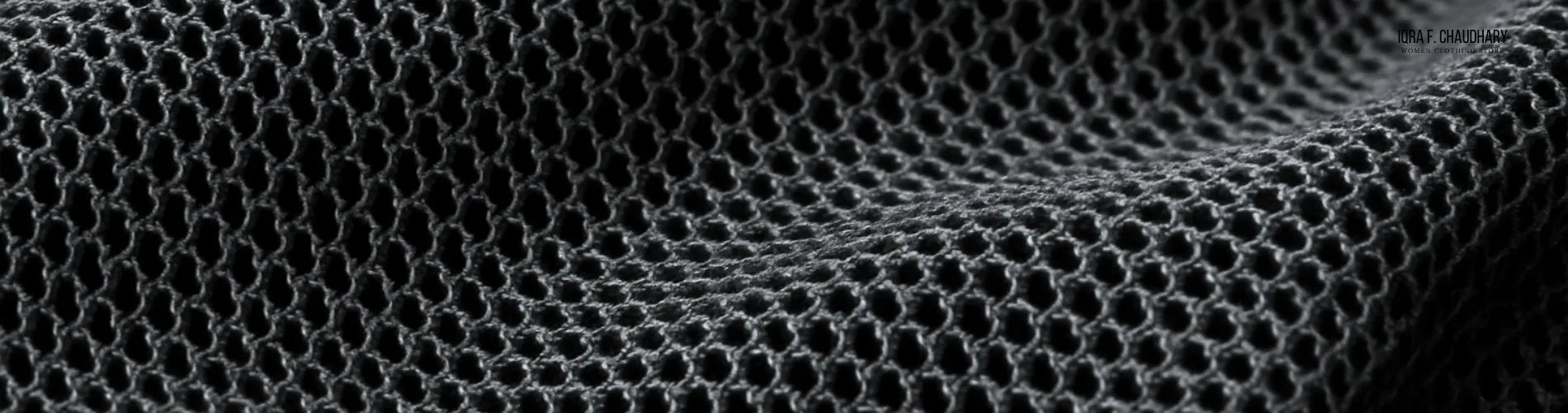

Mesh fabric is a textile with a regular pattern of open holes between yarns, created by knitting or weaving so that the structure looks like a grid or honeycomb.

Mesh fabric is not one fibre by itself; mills usually make it from polyester, nylon, cotton, spandex blends or other synthetics, with the open construction giving high airflow, low weight and fast drying. In clothing, people use mesh for sports jerseys, linings, pockets, panels in dresses and activewear where breathability matters more than full coverage.

What Are the Types of Mesh Fabric?

The types of mesh fabric are grouped by fibre, by construction and by intended use, which together explain why some mesh feels stiff and industrial while other mesh feels soft enough for lingerie and tops.

- Polyester mesh – Mesh made primarily from polyester filaments, common in sports jerseys, bags and shoe uppers. It dries quickly, resists shrinking and holds colour well.

- Nylon mesh – Mesh from nylon yarns, often used for laundry bags, backpacks, industrial filters and some sports gear. It has good abrasion resistance and flexibility.

- Cotton mesh – Mesh based on cotton or cotton blends, used for casual tops, polo shirts and fashion panels where a softer, more natural touch feels important.

- Power mesh – A dense, elastic mesh that blends nylon or polyester with spandex. It gives support and compression in shapewear, sports bras and body panels.

- Spacer mesh (3D mesh) – A three-dimensional mesh with two outer surfaces connected by filament piles, used in backpacks, shoulder straps and sports shoes for cushioning and airflow.

- Fine fashion mesh – Soft, smaller-hole mesh used for sleeves, yokes, overlays and inserts in dresses and tops. It can come in matte or slightly glossy finishes.

- Technical and industrial mesh – Coarser meshes used for nets, filters, sieves and protective gear, often with specific mesh counts and strength ratings.

What Is the History of Mesh Fabric?

The history of mesh fabric links older openwork textiles with modern synthetic-fibre knitting and industrial design.

- Early open structures in cloth appeared in netting, lace and crochet, where workers left deliberate gaps for decoration or function. Those methods came from hand processes rather than industrial mesh.

- With the rise of mechanical knitting and weaving in the nineteenth and early twentieth centuries, mills began to produce regular open fabrics for curtains, veils and utility nets.

- The invention of nylon and polyester in the twentieth century gave mesh a new role. Synthetic filaments allowed finer, stronger yarns with controlled diameters, which suited repeated holes without tearing.

- By the late twentieth century, sports brands adopted synthetic mesh broadly for jerseys, lining and footwear because the open structure improved ventilation compared with solid knits and wovens.

- Today mesh covers everything from industrial filters and safety wear to fashion tops, lingerie, performance leggings and overlays on dresses, with design and engineering teams treating it as a standard toolkit fabric.

How Is Mesh Fabric Made?

Mesh fabric is made by knitting or weaving yarns so that regular openings appear between threads, then dyeing and finishing the cloth to reach the needed handle and performance.

- Fibre and yarn preparation – Producers choose fibres such as polyester, nylon, cotton or blends, then spin or extrude them into yarns. For technical mesh, filament yarns give strength and low fuzz; for fashion mesh, finer and softer yarns matter.

- Knitted mesh – Many meshes come from warp-knitting machines (such as raschel or tricot) that form loops in patterns which leave open spaces. Adjusting stitch length and pattern changes hole size, stretch and strength.

- Woven mesh – Some mesh fabrics use a plain or leno weave with spaced yarns. Mesh count (threads per inch) and yarn diameter control openness, which is important in filters and screens.

- Three-dimensional mesh – Spacer meshes use two outer layers knit or woven in parallel with connecting pile yarns, which create a stable air gap between surfaces.

- Dyeing and finishing – After knitting or weaving, mesh goes through scouring, dyeing and heat-setting. Softening finishes, stretch recovery control and dimensional stabilisation refine the final feel and behaviour.

How Are Women’s Clothes Made from Mesh Fabric?

Women’s clothes made from mesh fabric use its open structure for breathability, controlled transparency and design detail rather than full coverage alone.

- Designers add mesh panels under arms, along side seams or across backs of tops and dresses to improve air movement without changing the main silhouette.

- Mesh sleeves and yokes give controlled transparency, letting skin or an under-layer show while keeping the rest of the garment solid in cotton, silk or synthetics.

- Power mesh appears in sports bras, leggings and shapewear as inner layers that add support and hold, often hidden between outer shell and soft lining.

- Casual tops sometimes use cotton or polyester mesh as the main body, with a camisole or slip underneath for coverage.

- Skirts, dresses and abayas may use a mesh outer layer over an opaque lining, so the garment reads as light and airy while still covering the body.

What Are the Properties of Mesh Fabric?

The properties of mesh fabric come from its open structure and fibre content. The structure gives high airflow, low weight and variable coverage, while the fibres set softness, strength, moisture behaviour and heat resistance.

- Breathability – Large open spaces between yarns allow air and water vapour to move easily, which makes mesh useful in hot and humid conditions.

- Weight – Mesh often weighs less than solid fabrics of the same fibre and yarn size, because much of the area is open space rather than yarn.

- Coverage – Depending on hole size and layer count, mesh ranges from semi-sheer to almost opaque when doubled. Single layers with large holes show skin or underlayers clearly.

- Strength and stability – Filament polyester and nylon meshes can handle tension and abrasion well, which suits sports, footwear and bags. Very fine fashion meshes need gentler handling.

- Stretch – Knitted mesh, especially with spandex, offers stretch and recovery, while woven mesh tends to have lower stretch unless elastomeric yarns enter the structure.

- Moisture and drying – Synthetic meshes do not hold much water inside the fibre, so they dry quickly. Cotton meshes absorb more moisture, which can feel comfortable but slows drying time.

- Handle and feel – Some meshes feel soft and smooth, especially those for lingerie and tops; others feel firm or slightly rough, particularly industrial or protective meshes.

How Is Mesh Fabric Used?

Mesh fabric is used anywhere designers and engineers need ventilation, partial visibility or low weight with reasonable strength.

- Sports jerseys, shorts and training tops in team wear and gym wear.

- Lining in jackets, bags, backpacks and caps, where airflow improves comfort.

- Panels and inserts in leggings, sports bras and performance tops.

- Pockets, wash bags, storage organisers and shoe bags that show contents and allow drying.

- Safety vests, reflective garments and technical workwear with high-visibility tapes on mesh bases.

- Filters, sieves, insect screens and industrial covers in engineering and agriculture.

Where Is Mesh Fabric Produced?

Mesh fabric is produced in textile mills that specialise in knitted and woven synthetics, cotton and blends, across many regions.

- Large volumes of polyester and nylon mesh come from synthetic textile hubs where filament spinning and warp knitting already exist on a big scale.

- Factories that make sportswear and footwear often run mesh production or buy from nearby knitting mills to feed jerseys, linings and uppers.

- Regions with strong technical textile industries supply spacer mesh and high-spec industrial mesh for filters, safety gear and automotive uses.

- Fashion and lingerie producers source finer, softer meshes from mills that focus on hand feel and dyeing rather than heavy technical performance.

What Are the Pros and Cons of Mesh Fabric?

The pros and cons of mesh fabric weigh breathability, low weight and design flexibility against snag risk, limited warmth and the need for lining in many garments. The next table simplifies those trade-offs.

| Aspect | Pros of mesh fabric | Cons of mesh fabric |

|---|---|---|

| Airflow and comfort | High airflow and fast evaporation help keep the body cooler during activity and in heat. | Low insulation means mesh gives little warmth on its own in cold or windy conditions. |

| Weight | Low fabric weight reduces bulk in sportswear, bags and footwear. | Very light meshes can feel too flimsy or see-through for people who prefer more coverage. |

| Coverage and modesty | Layered mesh allows designers to play with transparency and texture while keeping underlayers solid. | Single layers with large holes require lining or slips for modesty in many settings. |

| Strength and durability | Polyester and nylon meshes offer good strength and abrasion resistance for sportswear and gear. | Open structure snags on jewellery and rough surfaces more easily than flat weaves. |

| Care and drying | Most meshes wash easily and dry quickly, especially synthetic ones. | Fine meshes can distort if caught in machines or stretched while wet; some need laundry bags. |

| Design use | Panels, overlays and inserts give designers many options for shape, texture and ventilation. | Excessive mesh or poorly placed panels can weaken areas that need more support or coverage. |

What Is the Difference Between Mesh Fabric vs Net Fabric?

The difference between mesh fabric and net fabric is that mesh fabric usually means a regular, engineered grid made by knitting or weaving, while net fabric often refers to more open, sometimes knotted or twisted constructions used for tulle, fishing nets and classic net overlays. Both have holes, yet they differ in structure, stability and typical fashion roles.

| Aspect | Mesh fabric | Net fabric |

|---|---|---|

| Construction | Usually warp-knit or woven with regular, repeated openings; loops or crossings stay locked by the knit or weave. | Can be knotted, twisted or leno-woven; tulle nets use fine yarns in hexagonal or diamond patterns, and some nets use knots at intersections. |

| Hole shape and regularity | Holes often appear as uniform squares, rectangles or honeycomb shapes. | Holes may be diamond, hexagonal or irregular, and sometimes change size across the piece. |

| Feel and drape | Range from soft and stretchy (power mesh) to firm (spacer mesh); often built for comfort and function. | Tulle and fine net can feel very light and crisp; larger nets feel more coarse and open. |

| Typical garments | Sports jerseys, activewear panels, linings, bags and shoe uppers. | Veils, tutus, bridal net overlays, fishing nets, mosquito nets and some fashion net sleeves. |

| Design focus | Often used to balance performance and comfort in clothing and gear. | Often used to create volume, layered looks or functional nets rather than close-fitting panels. |

What Is the Difference Between Mesh Fabric vs Sheer Fabric?

The difference between mesh fabric and sheer fabric is that mesh fabric reaches transparency through visible holes in its structure, while sheer fabric reaches transparency through very fine yarns and a tight yet thin weave or knit without deliberate holes. Both allow light through, yet they give different surface looks and behaviour.

| Aspect | Mesh fabric | Sheer fabric |

|---|---|---|

| Structure | Open structure with holes between yarns; transparency comes from gaps. | Continuous structure with very fine yarns and low thickness; transparency comes from thinness. |

| Surface appearance | Grid, honeycomb or net-like look when viewed closely. | Smooth, veil-like surface without clear holes; examples include chiffon, georgette and organza. |

| Airflow | Very high airflow due to open gaps. | Good but lower airflow; air passes through yarn spaces, not large openings. |

| Touch and drape | Can feel slightly textured or sporty; drape depends on fibre and knit. | Often soft or crisp with more fluid or floaty drape in fashion applications. |

| Typical uses | Sportswear, linings, pockets, technical gear, some fashion panels. | Dresses, blouses, dupattas, veils, sleeves and overlays where a smooth sheer look is wanted. |

How to Care for Mesh Fabric

To care for mesh fabric people protect the open structure from snags and distortion, follow fibre-based washing rules and avoid harsh heat and friction.

- Check the fibre label; cotton mesh tolerates gentle cotton washing routines, while polyester and nylon mesh prefer cooler, synthetic-friendly settings.

- Use mild detergent and avoid bleach unless the label clearly allows it, because strong chemicals weaken yarns and any added elastane.

- Place delicate mesh garments in laundry bags so hooks, zips and machine parts do not catch on the holes.

- Wash on gentle cycles with low spin speeds to reduce stretching and twisting of the open structure.

- Dry flat or on hangers away from direct, harsh sunlight, which can weaken synthetic fibres and fade colours over time.

- Use cool to medium iron settings only when needed, and press through a pressing cloth. Many meshes do not need ironing if dried carefully.

- Store mesh garments so heavy items do not press and deform the holes; folding with light layers or hanging with enough space usually works well.